How lithium-ion batteries are recycled

Lithium-ion battery recycling involves collecting, discharging, and dismantling used batteries. Valuable metals like Li, Co, Ni, and Mn are extracted from the resulting black mass. Hydrometallurgical or pyrometallurgical methods recover these metals. The recovered metals are then reused in new batteries.

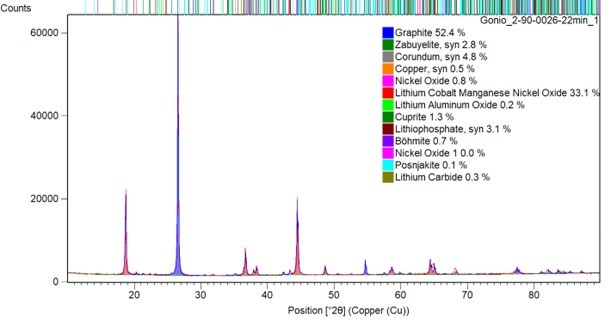

Challenges in recycling include the variety of battery chemistries, such as NMC and LMFP, with varying compositions. Accurate characterization of black mass is essential for efficient recycling.

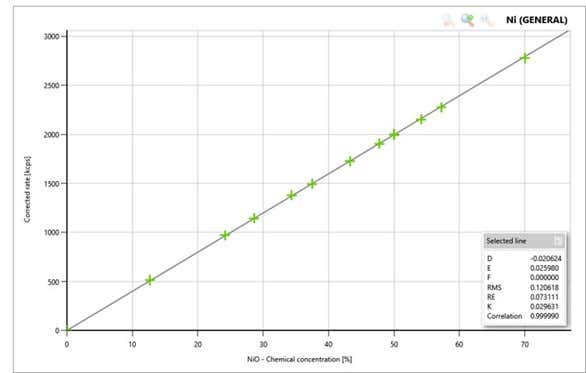

Our X-ray and neutron-based solutions can analyze chemical composition and crystalline phases. Our XRF solutions evaluate hydrometallurgical leaching efficiency and impurity analysis. Additionally, our particle size analyzers measure particle size throughout the recycling process.