What do you imagine when you think about the future? Everyone has their own answer to this question, ranging from flying cars to personal goals, but one aspect is usually the same, no matter who you ask. The future will be better!

It’s famously difficult to quantify what ‘better’ actually means – economists and sociologists don’t always agree! – but since industrialization began in the 18th century, a better future for society has always involved faster, safer and more efficient manufacturing. Today, many of us are conscious that we’re watching the dawn of a new era as automation defines our new manufacturing era as ‘Industry 4.0’.

Future Days

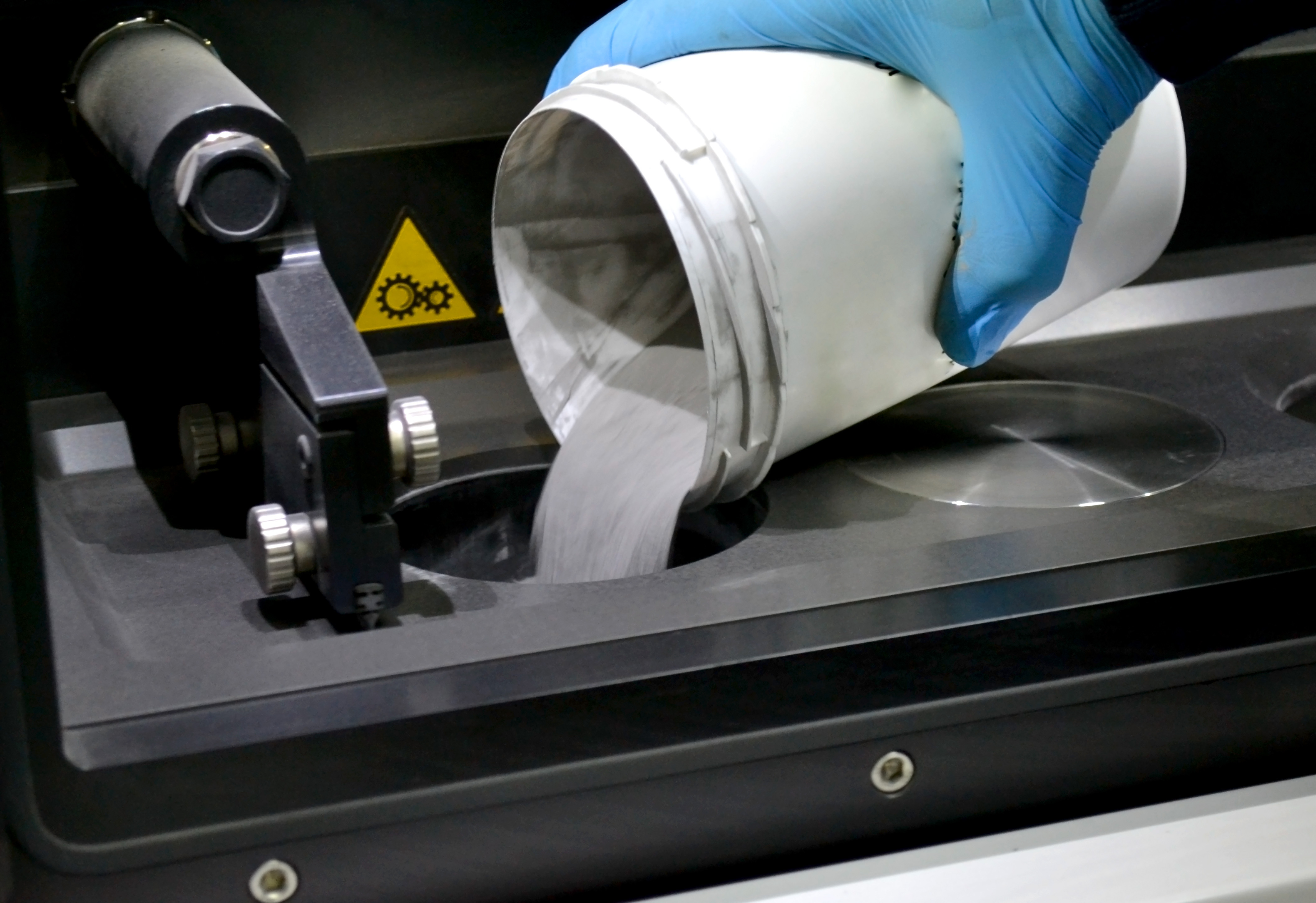

This exciting and optimistic vision was the background to our recent Future Days event, which featured an engaging mix of presentations from industry experts in advanced materials, including additive manufacturing (AM). They shared their personal takes on what challenges and opportunities might be around the corner for the AM community, and what they think the best approaches are to ensure AM fulfils its incredible potential.

Watch the video below